Interfaces in

functional ceramics: How to tweak material's properties?

Wolfgang's research group on

interfaces focusses on the fundamentals of interfaces in functional

ceramics,

specifically, the impact on processing and electric properties. The

focus is on

interfaces in ionic conductors for Li, H and O conducting

electrochemical

systems.

Interfaces

play a key role in materials processing and microstructure evolution of

ceramic

materials. Beyond that, many material’s properties are dominated by

interfacial

properties. This is most notable for mechanical properties of ceramics

where

the overall fracture behavior depends on the grain boundary structure.

For the

classical engineering ceramics silicon nitride and alumina, grain

boundary

fracture is well-known to depend on the formation of amorphous layers

depending

on the dopant concentrations. In alumina and many other systems, the

thermodynamics of these layers were investigated in detail

(‘complexions’). It

was shown that the complexions follow phase-like behavior enabling the

investigation of grain boundary phase and TTT diagrams.

But also

conducting materials critically depend on the conductivity of internal

interfaces. In most ceramic systems, such interfaces involve a charged

core

with an adjacent space charge. As soon as charge carriers are

transported

through the material, this space charge acts as Schottky barrier

resulting in

very low grain boundary conductivity. This poses a significant problem

for

applications in the field of ionic conductors as e.g. electrolytes in

SOFC or

solid-state electrolytes for Li batteries. Particularly, the

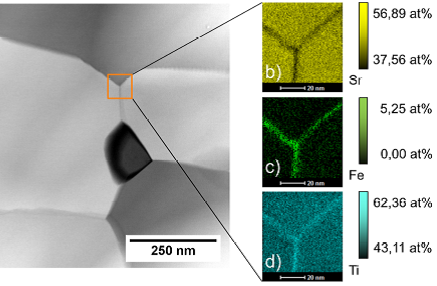

performance of CeO2,

LixLayTiO3 and BaZrO3

suffers from

poor grain boundary conductivity due to space charge.

For a few

model systems (alumina, zirconia, titania and strontium titanate), our

knowledge on the relationship between fundamental thermodynamics (i.e.

defects

and their chemistry) and some grain boundary properties is relatively

well

established. Beyond these systems, little is known on interfaces and

their

properties. This proposed project aims on both completing our knowledge

on

model systems and extending our current modelling such that space

charge is

added to the complexions framework. But more importantly, this

framework and

knowledge will be extended to more complicated material systems that

have a

higher relevance for electronic applications.

In this

regard, not only equilibrium situations are of interest, but also the

kinetics

of grain boundary phase transitions. If grain boundary phase and TTT

diagrams

can be established, roadmaps for tailored processing, microstructure

evolution

and optimized grain boundary properties become available.

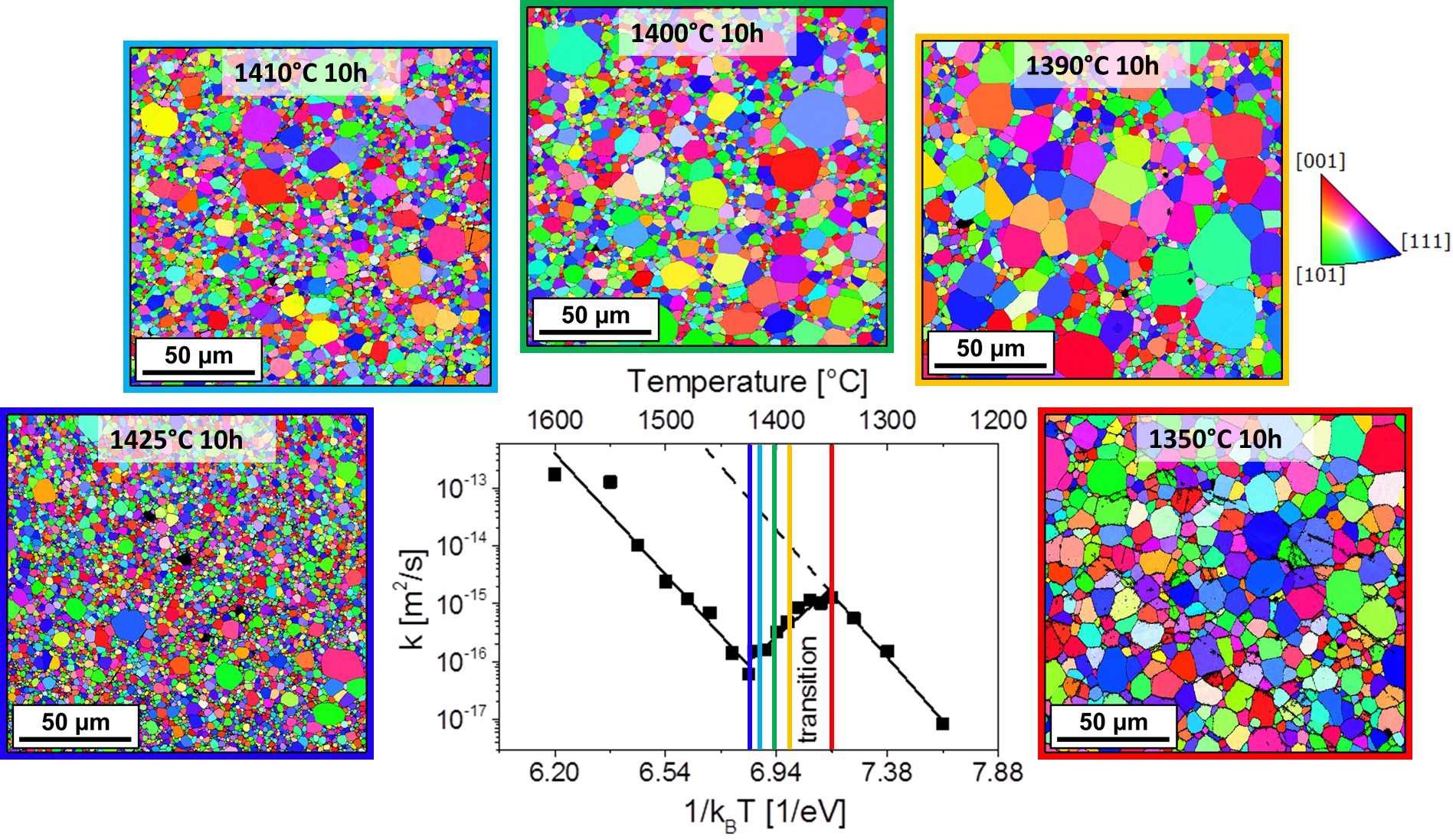

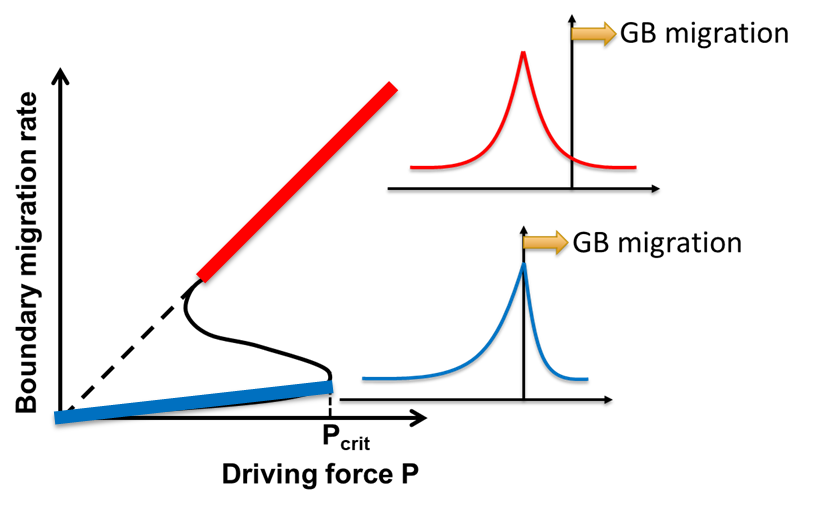

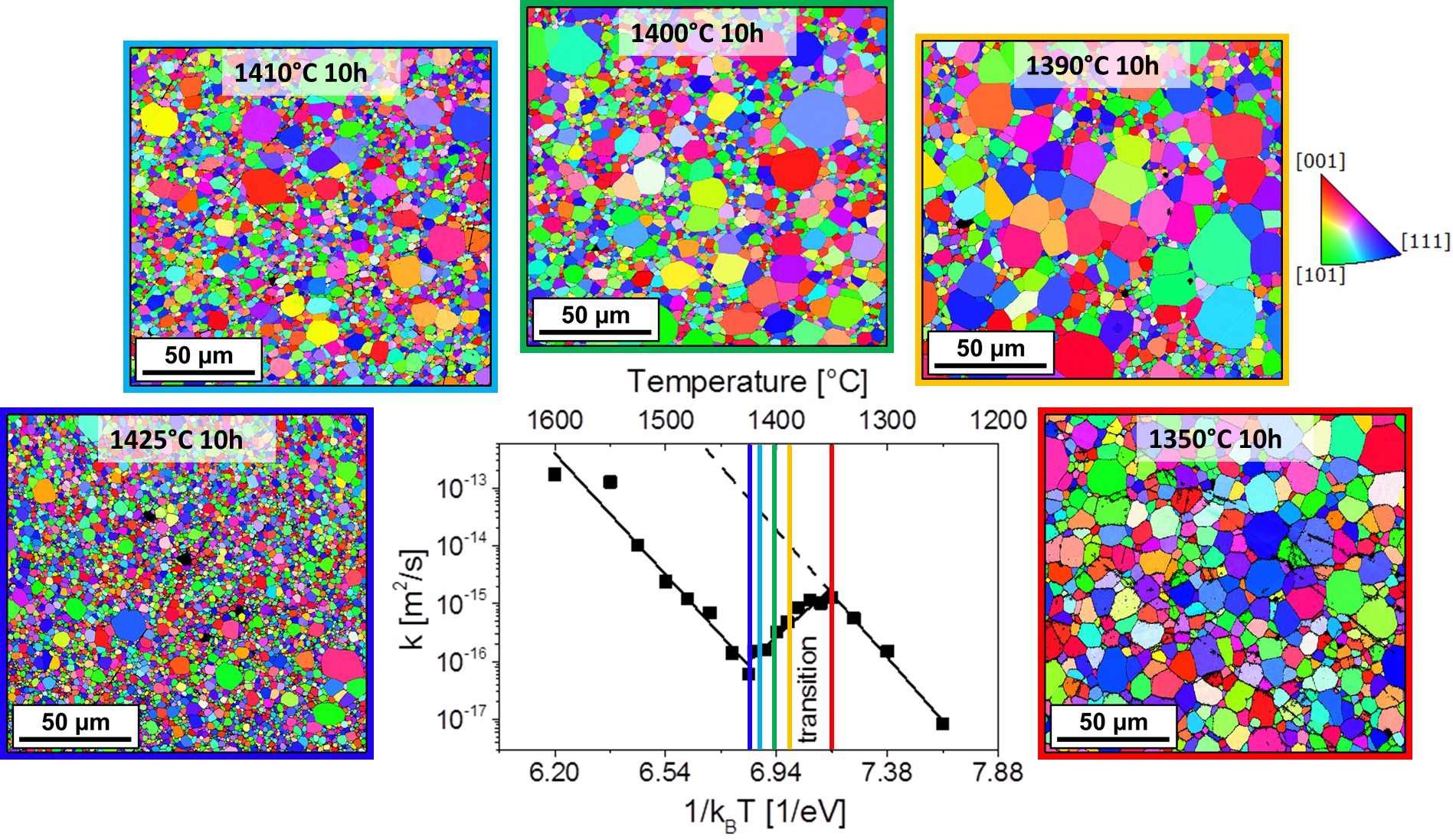

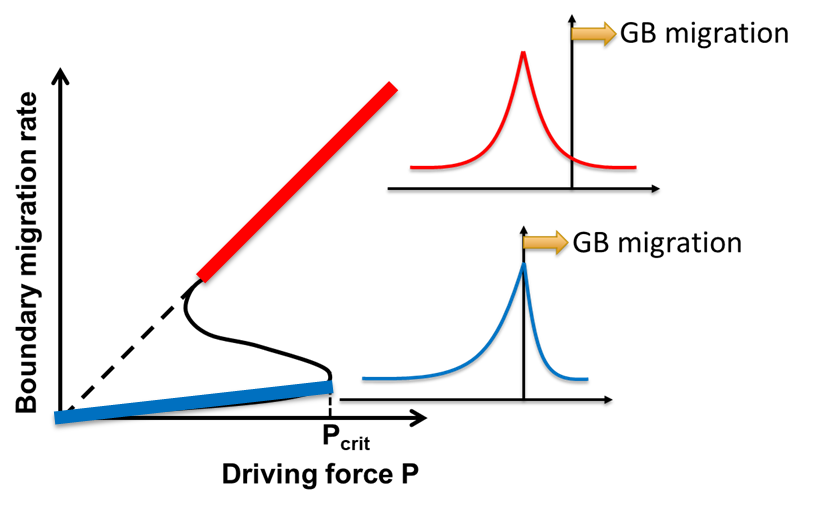

Grain

growth transitions in functional ceramics

In general,

microstructure evolution is believed to be a thermally activated

process due to

its dependence on mass transport by diffusion. However, in functional

ceramics

as the perovskite SrTiO3 and related materials,

non-Arrhenius

behavior occurs during microstructure evolution: at higher

temperatures, finer

microstructures can occur. This unexpected behavior is associated with

bimodal

microstructures and segregation. Its complete understanding allows

tailoring

microstructures according to a given need. Controlling the grain growth

rate

allows well-controlled unimodal fine-grained or coarse microstructures.

Even

quasi-single crystalline microstructures can be obtained with grains of

a size

of 100ds of µm, if segregation and space charge are carefully

engineered. This

high degree of microstructure control offers immense potential to

tailor

properties: both ionic and electronic conductivities of grain

boundaries are of

central importance e.g. for proton conductors (BaZrO3), Li

conductors (LixLayTiO3) and oxygen

conductors

(CeO2) and many other applications.

References

W.

Rheinheimer & M. J. Hoffmann: ‘Grain growth in perovskites:

What is the impact of boundary transitions?’, Current Opinion in Solid

State

and Materials Science, 2016

W.

Rheinheimer & M. J. Hoffmann: ‘Non-Arrhenius behavior of grain

growth in

strontium titanate: New evidence for a structural transition of grain

boundaries’, Scripta Materialia, 2015

W.

Rheinheimer, M. Bäurer & M. J. Hoffmann: ‘A reversible wetting

transition

in strontium titanate and its influence on grain growth and the grain

boundary

mobility’, Acta Materialia, 2015

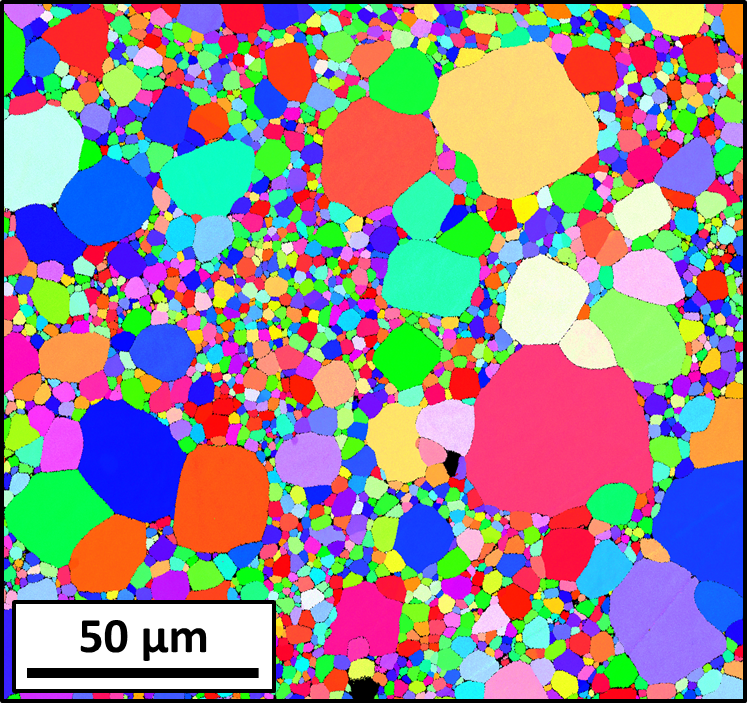

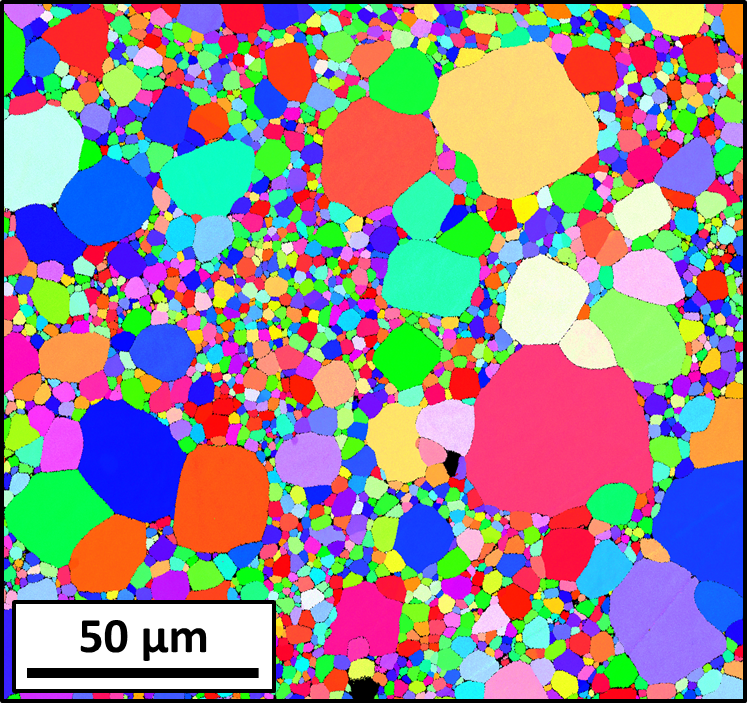

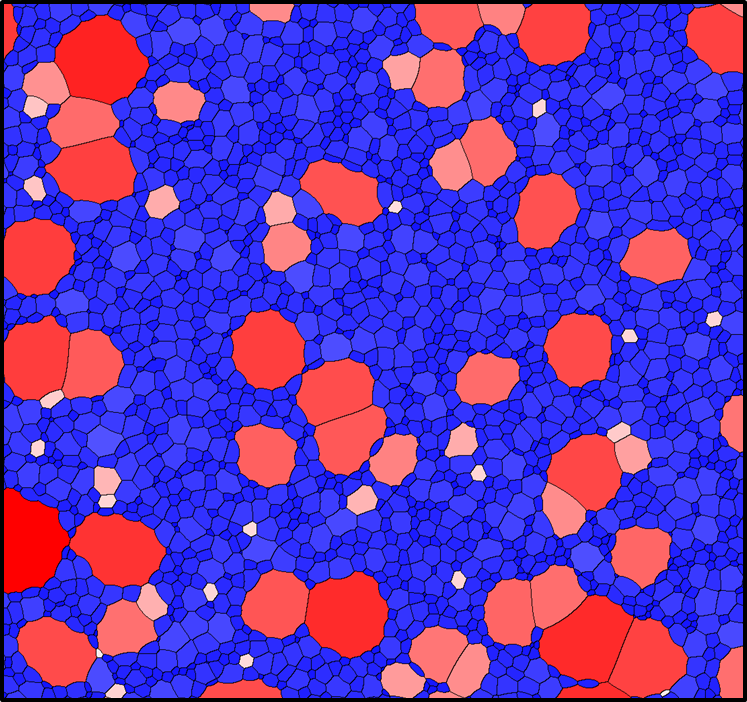

Simulation

of bimodal grain growth

To obtain

full microstructural control, a careful analysis of bimodal

microstructure

evolution is needed. This can only be achieved by establishing a

digital twin,

e.g. using a phase field model for bimodal microstructure evolution.

The obtained

numbers allow investigating nucleation behavior of bimodal

microstructures.

References

W.

Rheinheimer, E. Schoof, M. Selzer, B. Nestler & M. J. Hoffmann:

„Non-Arrhenius grain growth in strontium titanate: Quantification of

bimodal

grain growth“, Acta Materialia, 2019

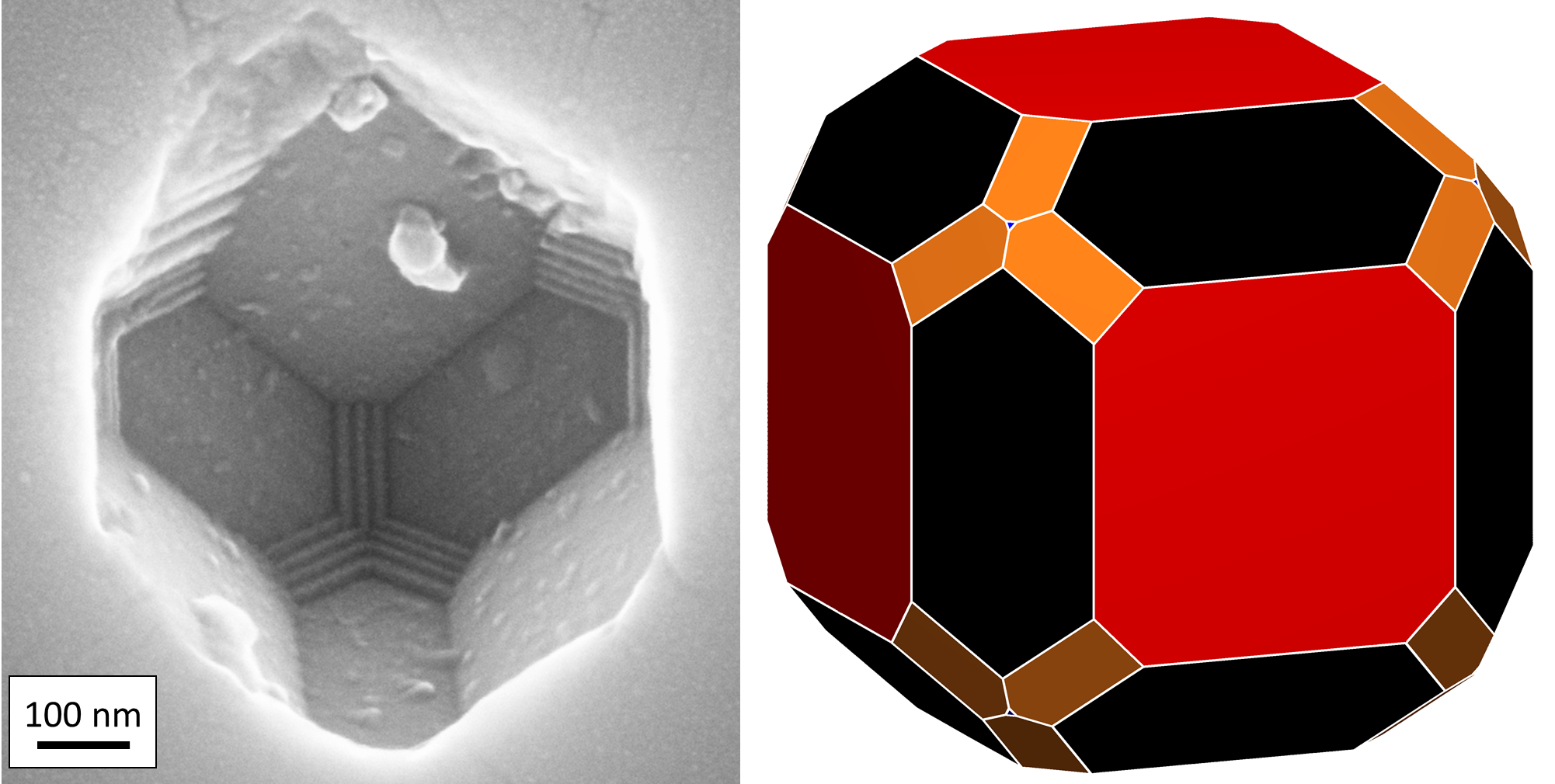

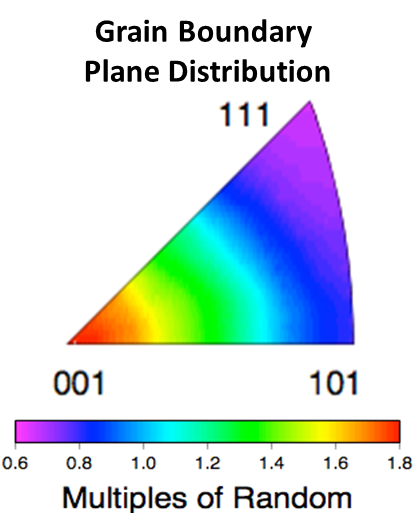

Anisotropy

and its impact on microstructure evolution

Due to the

crystalline nature of ceramics, lattices have anisotropic properties.

As a

consequence, all grain boundary properties are anisotropic as well,

e.g. the

grain boundary energy, and mobility, but also electric properties and

segregation. To evaluate the impact of anisotropy on microstructures

and

properties, careful model experiments are needed. For example, the

anisotropy

of the grain boundary energy can be approached by observing the shape

of pores or

grains in microstructures. Statistical approaches reveal the texture of

the

grain boundary plane orientation (Grain Boundary Plane distribution)

and allow

the identification of important grain boundary configurations.

References

W. Rheinheimer,

C. A. Handwerker

& J. E. Blendell: ‘Equilibrium

and kinetic shapes of

grains in polycrystals’,

Acta Materialia, 2020

W.

Rheinheimer, D. Lowing &

J.E. Blendell: ‘Grain growth in NiO-MgO and its dependence on faceting

and the

equilibrium crystal shape’, Scripta Materialia,

2020

W.

Rheinheimer, Fabian J.

Altermann & M. J. Hoffmann: ‘The equilibrium crystal shape of

strontium

titanate: Impact of donor doping’, Scripta

Materialia, 2017

W.

Rheinheimer, M. Bäurer, H. Chien, G. S. Rohrer, C. A. Handwerker, J. E.

Blendell & M. J. Hoffmann: ‘The equilibrium crystal shape of

strontium

titanate and its relationship to the grain boundary plane

distribution’, Acta

Materialia, 2015

W.

Rheinheimer, M. Bäurer, C. A. Handwerker, J. E. Blendell & M. J.

Hoffmann:

‘Growth of single crystalline seeds into polycrystalline strontium

titanate:

Anisotropy of the mobility, intrinsic drag effects and kinetic shape of

grain

boundaries’, Acta Materialia, 2015

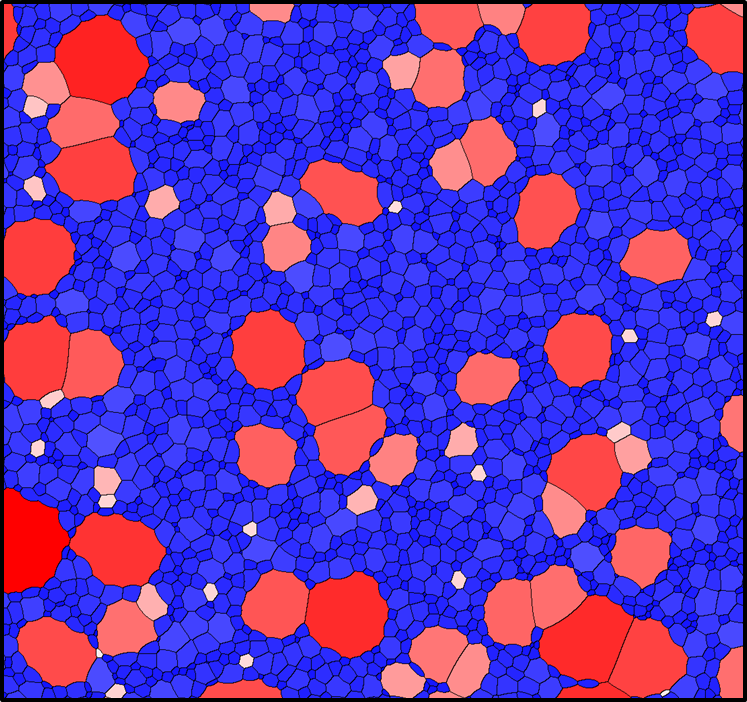

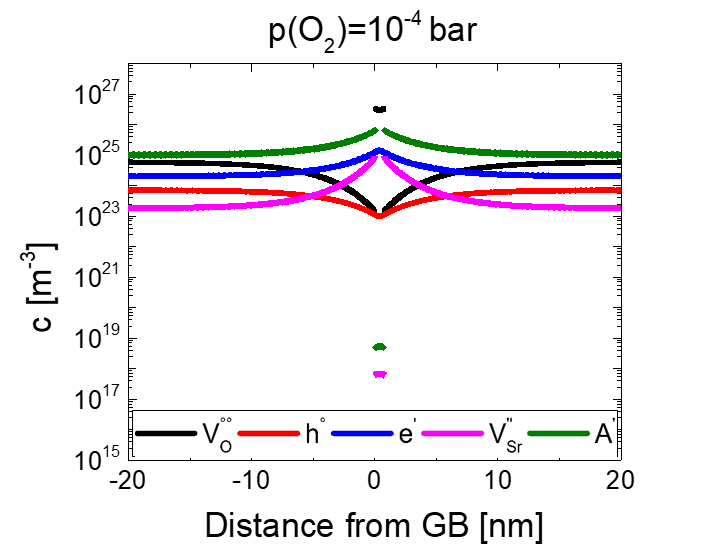

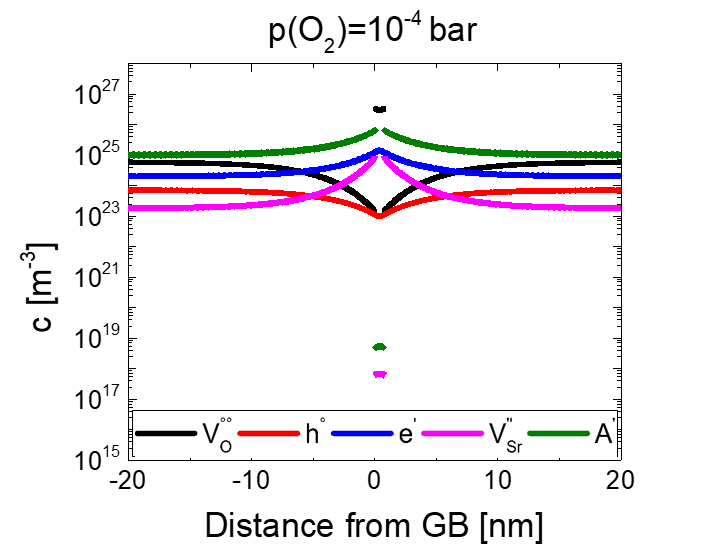

Space

charge, grain boundary segregation and solute drag in functional

ceramics

Space

charge

at a grain boundary forms for thermodynamic reasons: The grain boundary

is a 2D

lattice defect and results in a fraction of broken bonds and, as a

result,

lattice stresses. In response, the grain boundary restructures by

segregating

point defects to the grain boundary core. As these defects bring a

charge to

the grain boundary plane. This charge is shielded by an accumulation of

point

defects with inverse polarity next to the grain boundary core. Space

charge and

segregation are common in functional ceramics and sometimes decrease

the

performance by orders of magnitude due to the resulting Schottky

barriers. Less

well-known is the dependence of microstructure evolution on space

charge:

segregated defects can dominate densification and grain boundary

migration. The

underlying physics are known since the 60s from metals (‘solute drag’).

Accordingly,

tailoring microstructure evolution in functional ceramics for a given

application needs a fundamental understanding of space charge and

segregation.

This fundamental understanding is supported by well-established models

from the

metals community that need to be extended to account for the additional

complexity of ionic polycrystals.

References

W.

Rheinheimer & M. J. Hoffmann: ‘Grain growth in perovskites: What is

the

impact of boundary transitions?’, Current Opinion in Solid State and

Materials

Science, 2016

K.S.N.

Vikrant, W. Rheinheimer, H. Sternlicht, M. Bäurer & R. E. García:

‘Electrochemically-driven

abnormal grain growth in ionic ceramics’, Acta Materialia, 2020

K.

S. N Vikrant, W. Rheinheimer, & R. E. García: ‘Electrochemical drag

effect

on grain boundary motion in ionic ceramics’, npj Computational

Materials, 2020

W.

Rheinheimer, X. L. Phuah, H. Wang, F. Lemke, M. J. Hoffmann & H.

Wang: 'The

role of point defects and defect gradients in flash sintering of

perovskite

oxides’, Acta Materialia, 2019

W.

Rheinheimer, J. P. Parras, J.-H. Preusker, R. A. De Souza & M. J.

Hoffmann:

‘Grain growth in strontium titanate in electric fields: The impact of

space

charge on the grain boundary mobility’, Journal of the American Ceramic

Society, 2019

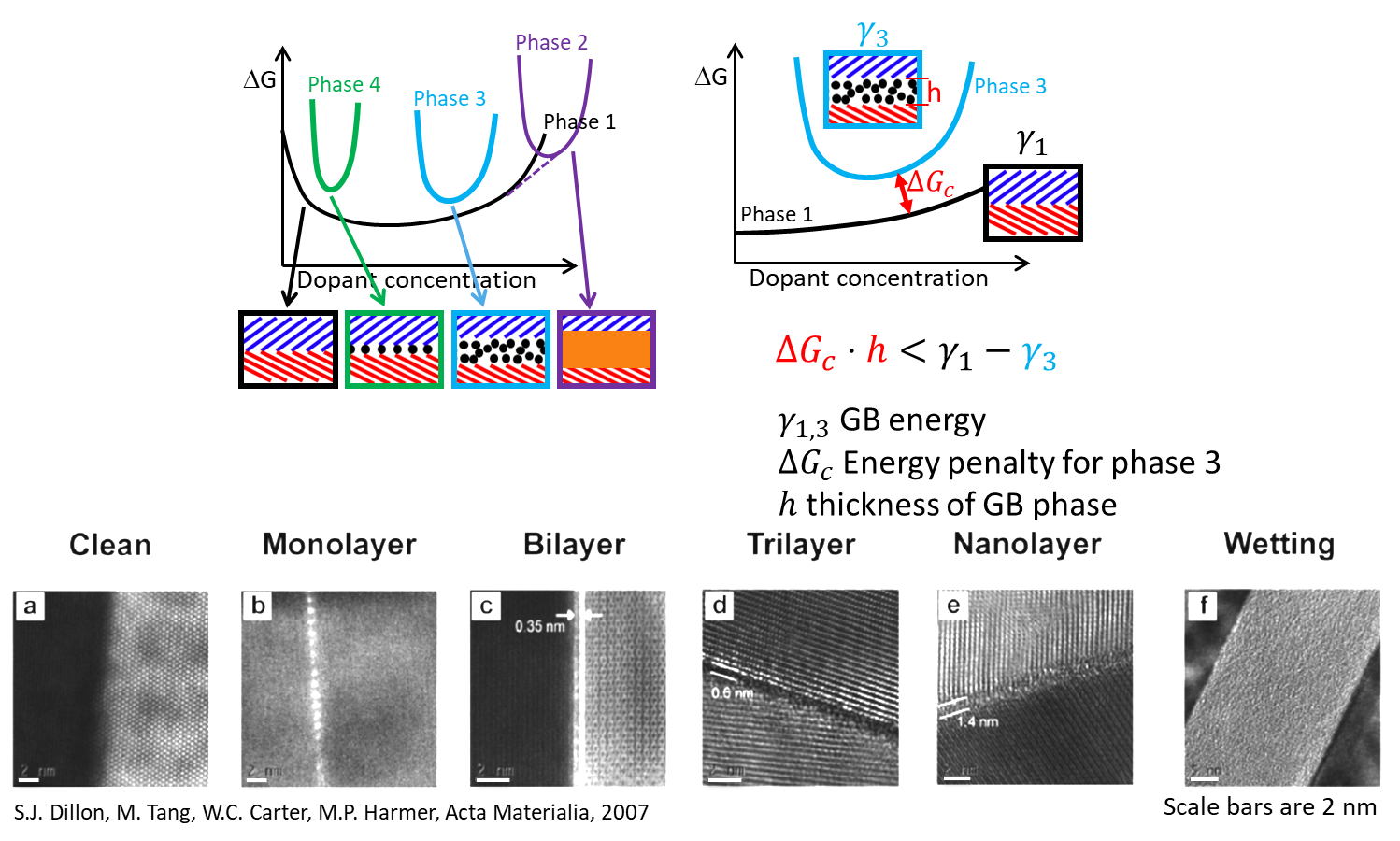

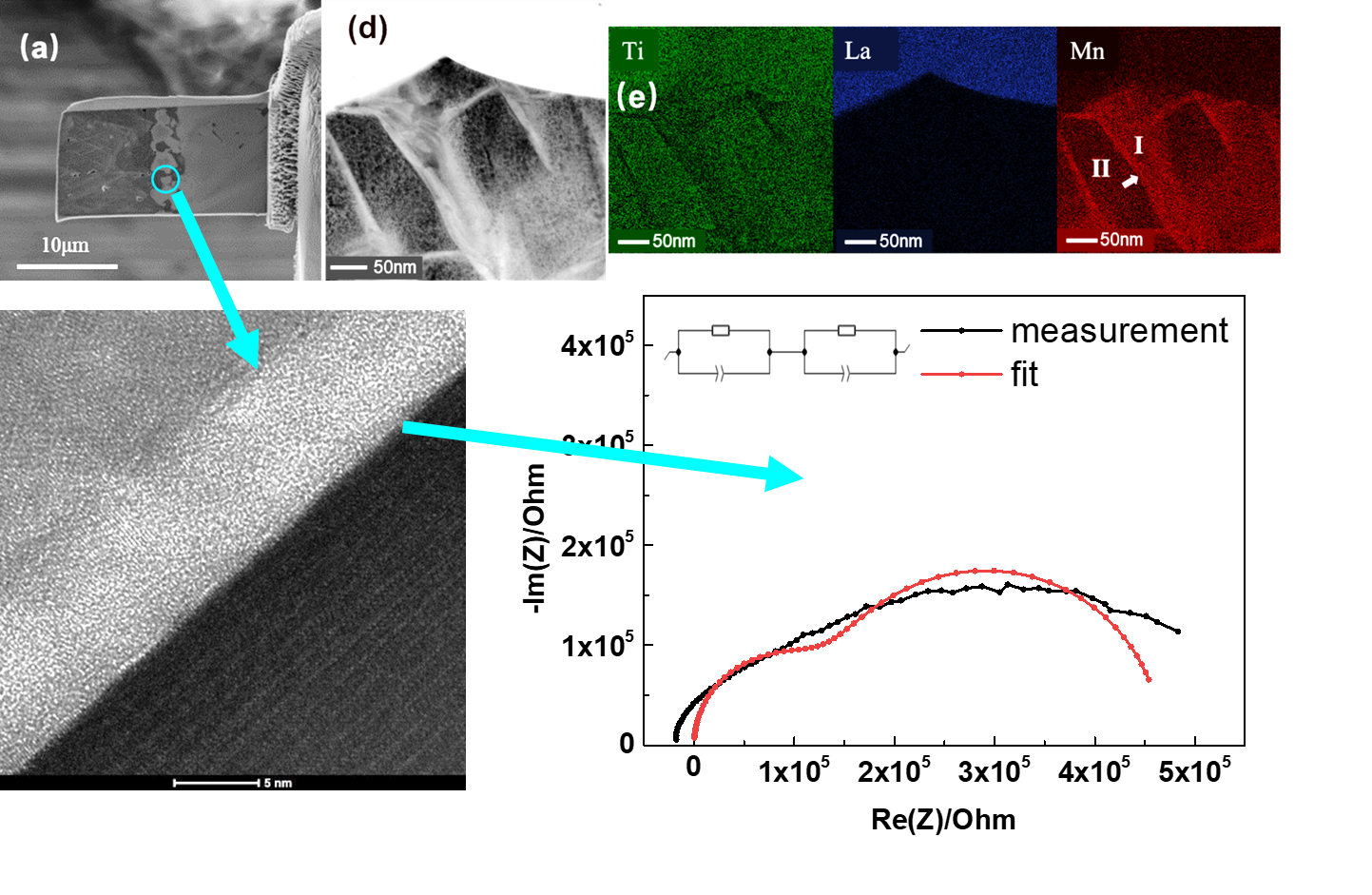

Grain

boundary adsorption and its interplay with functional properties

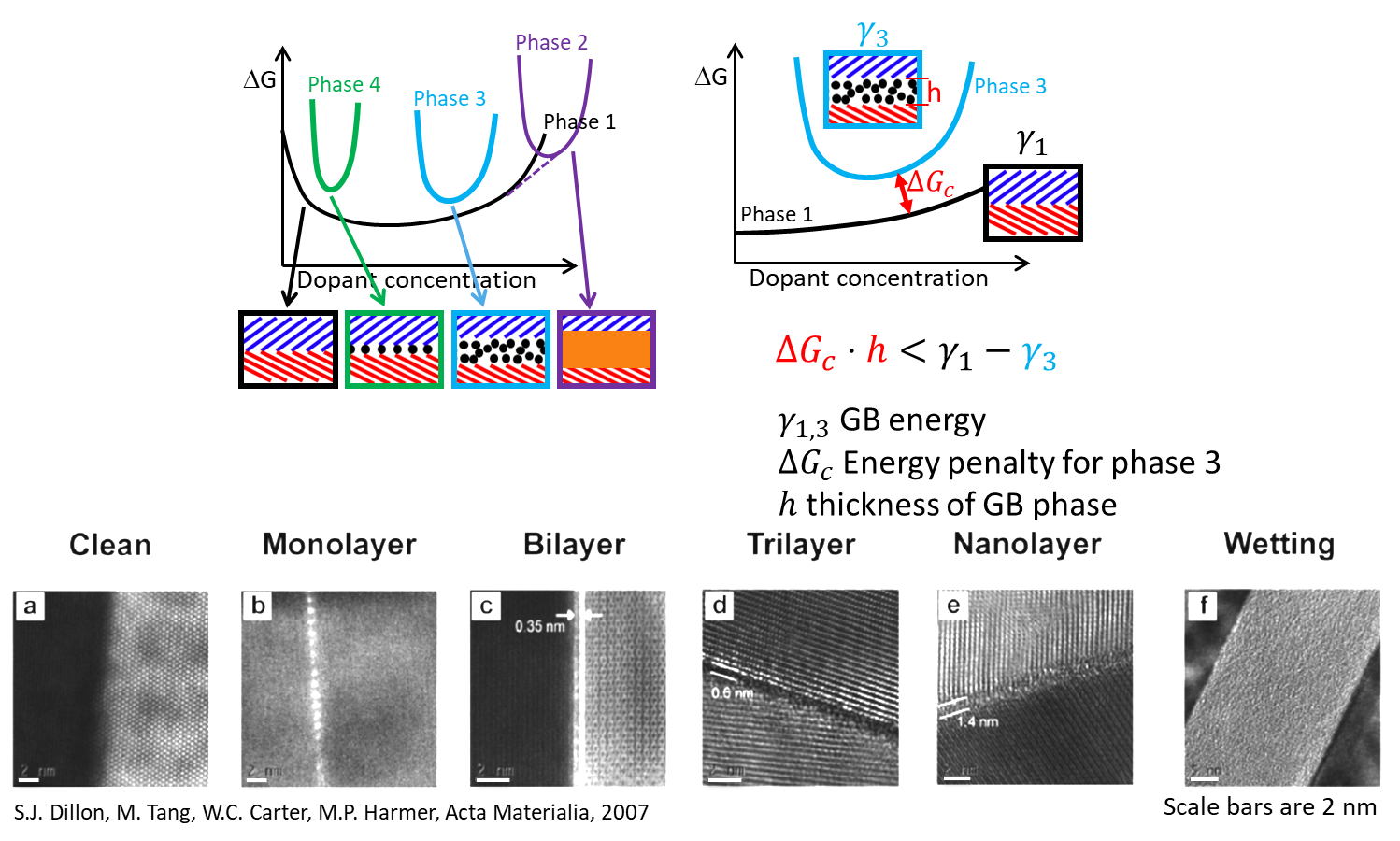

The

occurrence of adsorption and grain boundary phases in ceramic materials

is

known since the 90s, when the engineering ceramic Si3N4

was the investigated in detail. This concept bases on the thermodynamic

stabilization of adsorption layers by a reduction of the grain boundary

energy

and is known under the terms critical wetting, intergranular glassy

film (IGF)

or complexion.

Recently, the

phenomenon of grain boundary phases was revisited in the context of

microstructure evolution and functional properties. For example, in

LMO-LLTO

half cells for solid state batteries, nm-thick layers of amorphous

grain

boundary phases result in enormous interfacial resistance. Such an

interface is

unusable for solid-state batteries.

References

P. Xu, W.

Rheinheimer, S.N. Shuvo, O. Levit, Y. Ein-Eli & L. Stanciu: ‘Origin

of high

interfacial resistances in solid-state batteries: interdiffusion and

amorphous

film formation in LLTO/LMO half cells’, ChemElectroChem,

2019

W.

Rheinheimer & M. J. Hoffmann: „Grain growth in perovskites: What is

the

impact of boundary transitions?“, Current Opinion in Solid State and

Materials

Science, 2016

W.

Rheinheimer, M. Bäurer & M.

J. Hoffmann: ‘A reversible wetting transition in strontium titanate and

its

influence on grain growth and the grain boundary mobility’, Acta Materialia, 2015

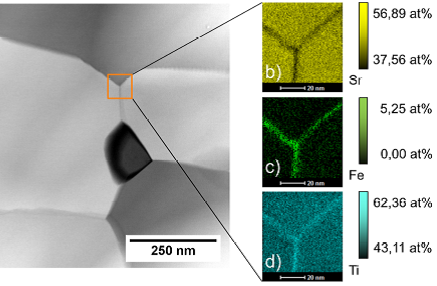

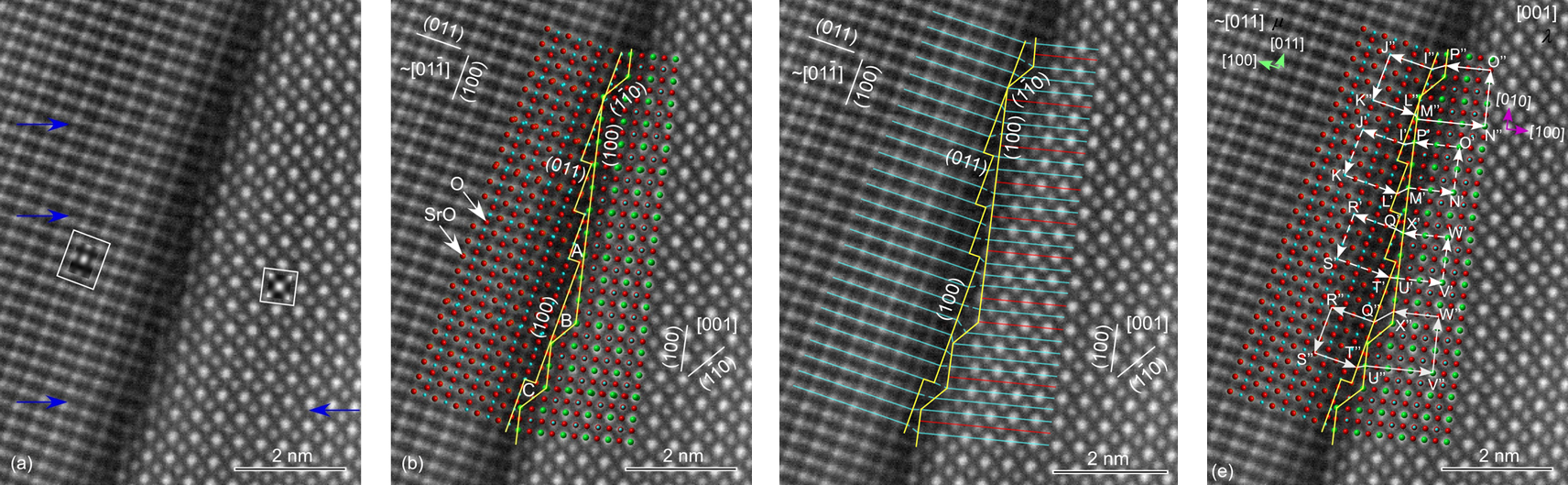

Grain

boundary structure and microstructure evolution

On atomistic

scale, the motion of grain boundaries is believed to base on the

movement of

steps and grain boundary dislocations (‘disconnections’). This

mechanism is overlaid

by other grain boundary effects as e.g. space charge and solute drag.

References:

H.

Sternlicht, W. Rheinheimer, A. Mehlmann, A. Rothschild, M. J. Hoffmann

& W. D. Kaplan: „The mechanism of grain growth at general grain

boundaries in SrTiO3“, Scripta Materialia, 2020

H. Sternlicht, W.

Rheinheimer, R. E. Dunin-Borkowski, M. J. Hoffmann & W. D. Kaplan:

‘Characterization of grain boundary disconnections in SrTiO3 part I:

The dislocation component of grain boundary disconnections’, Journal of

Materials Science, 2019

H. Sternlicht, W.

Rheinheimer, J. Kim, E. Liberti, A. I. Kirkland, M. J. Hoffmann &

W. D. Kaplan: ‘Characterization of grain boundary disconnections in

SrTiO3 part II: The influence of superimposed disconnections on image

analysis’, Journal of Materials Science, 2019